The Knives use diferents types of steels and coatings to give them the form and hardness required. In the following list shows some types of steel used habitually.

-

420H (High Carbon content)

420 steel with high Carbon content. Very stain

resistant and tough. Easy to re-sharpen. -

“MOVA” 1.4116 (X50CrMoV15)

It´s a classic steel in our Knives and folding Knives.

A excellent combination of Molybdenum and

Vanadium that is highly stain resistant, though,and

corrosión resistant. -

“MOVA 60” (X60CrMoV15)

More content in Carbon than MOVA (1.4116).

-

SANDVIK 14C28N

One of the best stainless steel to make Knives.

Contain nitrogen which enables and provide to

14C28N and excellent corrosion resistance and the

ability to be hardened to 58-61 Rockwell. -

DAMASCO (CARBON STEEL)

“Damascus steel” of 576 layers forged by hand

following ancient techniques. -

DAMASCO INOXIDABLE

The “Stainless Damascus Steel” it´s compound about

130 layers although it can range between 90 and

130 depending on the thickness and production.

Using two kind of rapidly solidified powder steels

(RWL34-PMC27) welded at a temperature of 1150ºC

and at a gas pressure of about 1000 atmospheres, we

get a material hard, durable, heat resistant and the

fracture strength thereby increased radically. -

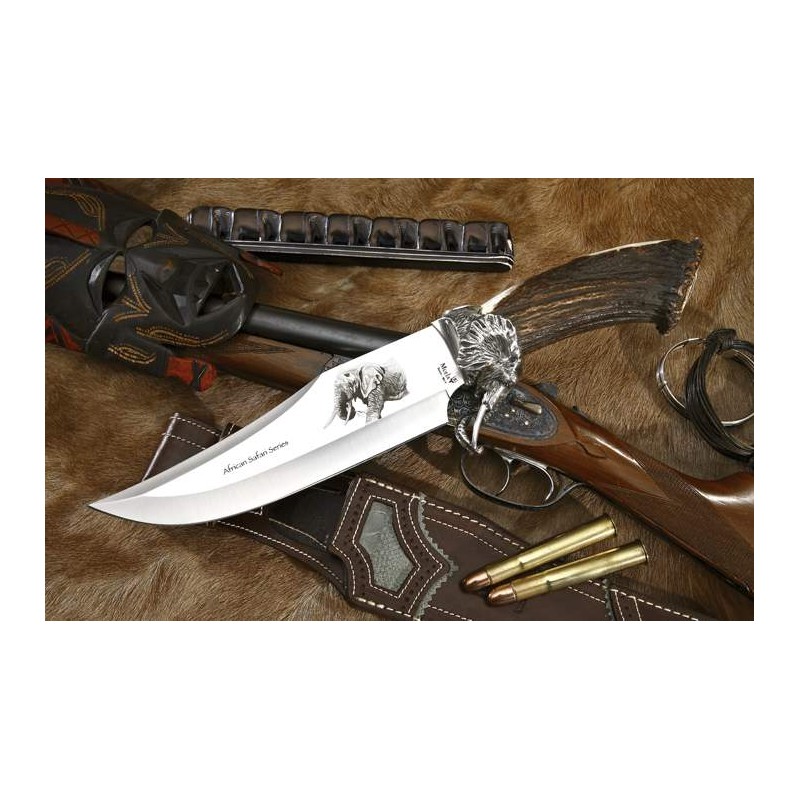

DAMASCUS VG10

Hand-Crafted made like old Samurai swords, these

Traditional Japanese kitchen Knives, use a VG10

laminated blades. The VG10 High Carbon Cobalt core

is clad with 7 layers of stainless steel (410) on each

side, producing a beautiful 15 layers Damascus. VG10

is known the “Super Steel” that holds an edge longer

than other steels.

BLADE COATING.- TEFLON (PTFE)®

Anti-friction PTFE coating used on knives and blades. It is practically inert and does not react to other chemical substances, with a very low friction coefficient and high impermeability, preserving its quality in moist environments. As such, this is an excellent anti-corrosion treatment, and is highly appreciated for tactical or military use.