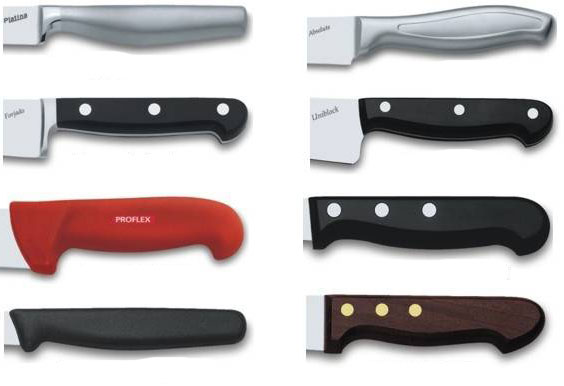

The Knives use diferents types of materials and coatings to give them the hardness required. In the following list shows some types of materials used habitually to knives handles.

-

MICARTA®

A composite of linen, canvas that is impregnated with epoxy resin and formed into sheets or blocks. Extremely resistant to water,wear,heat,etc…

-

PAKKAWOOD

This is a natural wood composite (cocobolo, coral, birch…) soaked with resin, and at times dyed. When subjected to pressure and temperature, it obtains better properties than the wood itself that makes it up, such as greater hardness and water resistance.

-

PBT + FIBRE GLASS

PBT is an engineering polymer with excellent thermal, mechanical, electrical and chemical properties. Its fibre glass reinforcement bequeaths it with greater hardness and tenacity, and therefore greater wear resistance. In addition to excellent chemical resistance, which makes it practically indifferent to weather and light, it also has good

thermal properties, withstanding temperatures greater than 200ºC. It is non-toxic and totally recyclable. -

ANODIZED ALUMINUM 5083

Anodizing makes aluminum stronger and anodic films are much longer lasting than other surface colorations. Anodized aluminum knife handles are highly scratch resistant and fade resistant.

-

NICKEL SILVER

This is a ternary alloy with Copper, Zinc and Nickel, with a colour and shine similar to silver. With a greater proportion of Nickel, the quality and resistance to corrosive elements increase.

-

BRASS

This is a Copper and Zinc alloy made in furnaces at a smelting temperature of 980º C.

-

ZAMAK

It´s a family of alloys with a base metal of zinc and alloying elements of aluminium, magnesium, and copper.